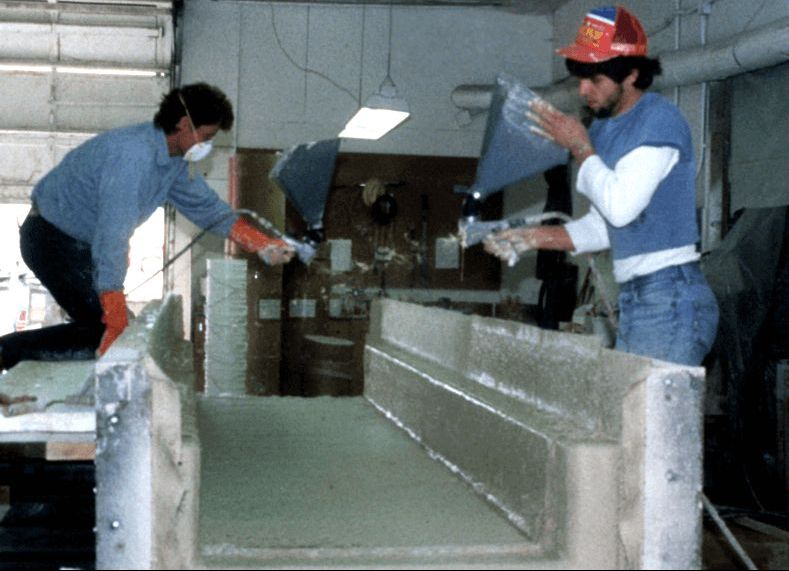

The Spalding Building was a job of firsts for Architectural Castings. It was the first design build project we ever took on, the first project that involved Glass Fiber Reinforced Cement elements, and the first time we created modules of parts with false joints included, rather than creating each block individually. It was also the last job we took on as general contractors, as we realized our strength was in the design and supply of components to facilitate masonry restoration, not their installation.

The building, designed by Cass Gilbert, was completed in 1911 just as work was being finished on his New York project, the Woolworth Building. The Spalding building had been modernized in the 1950s, with the original façade’s columns and spandrels filled in with brick and covered over with granite and travertine marble panels. In 1982, it was placed on the Historic Register, and Architectural Castings took on the restoration of the storefront façade in 1984.

Pioneer Waterproofing was engaged to do the masonry restoration, and they were able to replace the upper cornice using all original parts that had been cleaned and patched. Unfortunately, this was not the case for the storefront façade. When we pulled off the stone facing of the modernization from the '50s we found the belt course, capitals and bases had been sheared off and in-filled with brick. Demolition of the modernized façade did lead to the happy discovery of the original cast iron window grills, which were restored and utilized in the restoration.

We employed a multiple materials approach with this job, both for cost saving benefits and to suit the needs of the restoration. The primary replacement material for the belt course was sheet metal, but it also incorporated FRP and cast aluminum elements. The columns, capitals and bases of the storefront incorporated both GFRC and formed sheet metal. One trade-off of using the more cost-effective sheet metal cornice option is that the paint finish can never completely match the finish of the GFRC façade elements.

Before and After Photos

Additional Photos

The first floor of the building was originally a high-ceiling lobby with an ornamental plaster ceiling. During the ‘84 renovation we installed steel beams across the window openings to accommodate a mezzanine level. We were able to saw cut the sides of the newly produced GFRC spandrel panels on-site to allow for the steel mezzanine crossbeams, and so the GFRC would fit properly against the granite.

Installation of the GFRC column modules had to be completed at night to prevent tying up the busy downtown street during daytime traffic. We created a cantilevered rigging system to allow us to lift and slide the columns into place. We then attached the columns with embedded steel strap anchors. Modularization – multiple parts combined to form one larger part, with false joints that maintain the original appearance – aided in a quick installation.